40 Years of Pioneering Rotomoulding in South Africa

In 1982, the Pioneering Spirit of the Wiid family inspired [name] to establish the foremost company in Rotomoulding in South Africa. Here we are 40 years later, enjoying the fruits of our labour with ever-expanding knowledge and territory of plastic moulding.

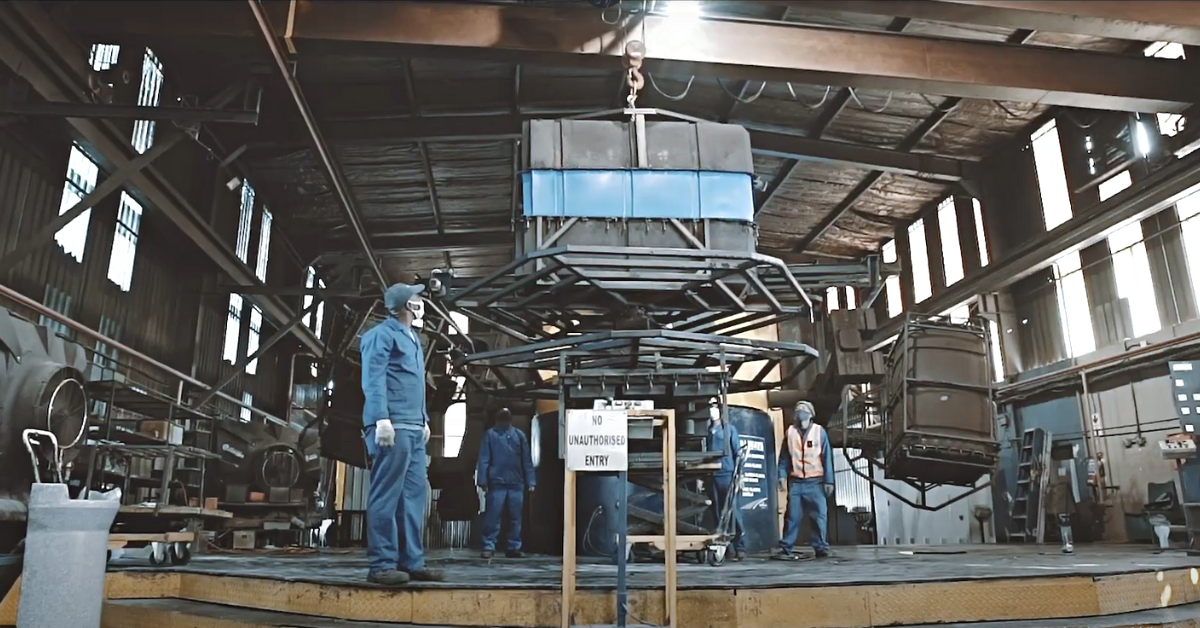

Here's a look into the world of rotational moulding, how it works and its advantages.

What Does Rotomoulding Mean?

There are several ways to mould plastic. The most popular types of plastic moulding are extrusion moulding, compression moulding, blow moulding, injection moulding and rotational moulding.

Rotational moulding is often called rotomoulding in South Africa and abroad. Rotomoulding involves transforming complex shapes into cost-effective products.

Sometimes people think of injection moulding and rotational moulding as the same thing—but there are differences.

What Is the Difference Between Injection Moulding and Rotomoulding?

Rotomoulding can produce hollow objects, whereas injection moulding produces solid ones. This is due to the processes and nature of the raw materials—polymers—that they use. These factors also affect the price of the products.

Let's look at how rotational moulding works

The Rotational Moulding Process in A Nutshell

Rotational moulding is a manufacturing process that uses a closed mould and heat to produce hollow, solid or semi-solid parts of any size. The process is carried out with polyethylene, a versatile, readily available material.

The polyethylene, in powder form, is poured into the closed (hollow-shaped) mould. The mould is heated and rotated slowly in vertical and horizontal planes. During this process, the polyethylene melts and evenly coats the inside of the mould. The process is precise, meaning that the walls of the product will have a uniform thickness.

Once cooled, you will have a hollow product with one continuous surface. So, unlike injection moulding, where two solid sides need to be fitted together, you won't have any seams.

Examples of Rotomoulded Products

The possibilities are virtually endless when it comes to rotomoulding in South Africa. That's why our motto is "Anything's Possible"

Rotomoulded products are seamless, robust, rustproof, odour-resistant, and food safe! For these reasons, the most common rotomoulded products are:

Rotational moulding creates the perfect lightweight yet hardwearing products:

Finally, durability and cost-effectiveness are the main drivers of these products:

We haven't even scratched the surface! If you want to see more, visit our home page.

The Advantages of Rotomoulding in South Africa

The rotational moulding process has been around for decades, but lately, rotomoulding in South Africa is more popular than ever.

That's because of the numerous advantages of rotational moulding:

- It is an efficient way to create plastic products.

- The process uses less energy than injection moulding, creating less greenhouse gas emissions.

- It can produce large quantities of items with little waste, saving on production costs.

- The finished product often looks better because it doesn't have seams like injection moulding.

The Perfect Answer for Prototyping

Rotational moulding lends itself well to prototyping because your imagination only limits you. Look no further if you're looking for custom conceptualisation, design, and production.

We're only too happy to help you innovate, one rotomoulded product at a time. Feel free to contact us to discuss your goals and ideas.